Just imagine: a render you could apply over the walls of a building, to protect it from collision damage. Sounds like magic?

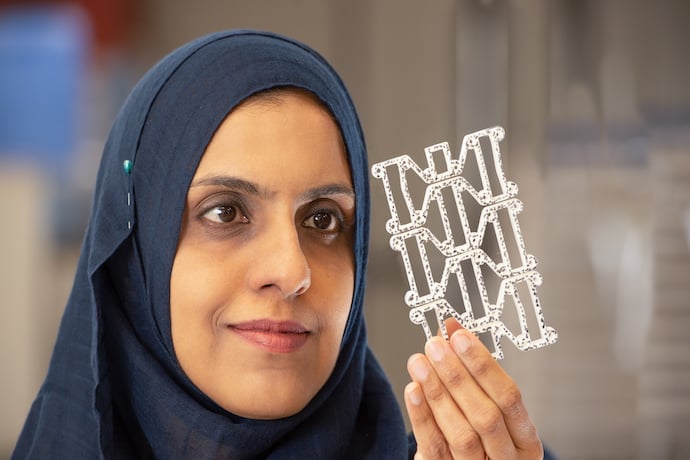

It could be closer to reality than you think, thanks to engineer, Dr Tatheer Zahra from the Queensland University of Technology. She’s working on a unique, 3D-printed product that could be embedded inside a cement-water mixture. When applied to the outside of a building, it could provide a protective, energy-absorbing layer to protect buildings from collisions, gas explosions, earthquakes and winds. The secret behind it? Auxetic geometries.

“Auxetic geometries are able to absorb a lot of energy,” explains Tatheer. “This is because, rather than flatting when stretched or bulging when compressed, auxetic materials expand or contract in all directions at once. My idea is to manufacture these geometries through 3D printing, then embed these geometries within a render that can be applied to a wall. If the building experiences a collision or impact force, the layer will absorb the shock energy, and protect the building.”

Tatheer, a lecturer and researcher in civil engineering, says she was inspired to experiment with these geometries after noticing them being used in other applications. “Auxetic geometries are already used for energy absorption in sports shoes, helmets and body armour,” explains Tatheer. “They’re also used in biomedical engineering, in high compression bandages, and in making catheters that enlarge the arteries. I thought to myself, if the material is good for shock absorption in sports, maybe we can apply it in shock absorption for buildings?”

At the moment, Tatheer is experimenting with the thickness of render, with her preliminary experiments showing that a 20 millimetre [3/4 inch] thick layer could withstand the force of a car travelling at 60 kilometres per hour [37 miles per hour].

An exciting example of engineering in action, Tatheer says the next step is to test the idea on full-scale masonry and concrete structures. “The theory and small-scale testing have shown positive results, and I’m looking forward to testing the idea on a larger scale, later this year,” says Tatheer. “I’m very interested in making structures more resilient to disastrous forces. Hopefully, in the future this can be a very helpful product in the civil engineering industry.”

Learn More

What are auxetics?

https://en.wikipedia.org/wiki/Auxetics

auxetics definition

https://www.definitions.net/definition/auxetics

auxetics

https://materiability.com/portfolio/auxetics/

Auxetics applications and possibilities

https://www.youtube.com/watch?v=ErnvTsCRDrs

Negative Poisson Ratio

https://www.youtube.com/watch?v=oLU-k7LhtZI

Dr Tatheer Zahra

https://research.qut.edu.au/cms/people/tatheer-zahra/

tatheer-zahra profile

https://www.stemwomen.org.au/profile/tatheer-zahra

Running shoe material inspires building protection

https://www.qut.edu.au/research/article?id=178836

Auxetics: Don’t Pull Me, I’ll Get Fatter

https://www.iucr.org/news/newsletter/volume-27/number-2/auxetics

Auxetic Smart Structures

https://www.piper3dp.com/blogs/from-the-lab-auxetic-smart-structures/

Clothes That Grow

https://thepanoptic.co.uk/2017/12/15/clothes-that-grow-petit-pli/