It’s April. I’m getting up early in the morning, earlier than usual at least, throwing on my 3D printed Montana Mask, and heading out the door to my job—well, my volunteer job at least. I’m running a small 3D printing lab for Multnomah County.

What are we doing? Making personal protective equipment (PPE) for our local medical school hospital and our school district, who need protection for workers serving food to kids who would normally rely on school lunches.

I’m one of dozens of people across this city alone 3D printing PPE. We’re mostly making variants on this design from Prusa Research, one of the big 3D printer manufacturers.

I don’t need to tell any of you about COVID-19 or how it affected everyone: classes and sports cancelled, nowhere to go, no friends you can visit. What you might not have heard is exactly why all of this ended up happening and why PPE was in such short supply.

Essentially, COVID-19 was unusually contagious: it’s called the novel coronavirus because it’s an actually new virus that none of our bodies had ever seen or fought before. This, in turn, means that our immune systems are, while not useless, not able to fight against it effectively so all the defenses that keep you from

- getting sick

- not dying when you are sick

don’t work like they normally would.

This extreme contagiousness means that in order to perform basic services medical and other frontline professionals need protection in ways they normally wouldn’t! You see, COVID-19 is droplet based which means that—and this is a little gross—you have to catch it by getting droplets of snot and spit from an infected person on your mouth, nose, eyes, or ears. So you’re most in danger from people coughing or sneezing on you or accidentally touching your face after touching something someone just recently coughed and sneezed on.

Thus if you can block big droplets then you can make it so much less likely that you’ll catch COVID-19. That’s where these face shields come in: the headband is 3D printed and on it you attach a thin, laser cut, plastic sheet that sits in front of your face and blocks any sneezes and coughs and also makes it less likely you could touch your own face without meaning to.

But a really good question is “Why did everyday people and hackerspaces have to make these? Don’t we have factories?” and this is where we get into the advantages and disadvantages of 3D printing!

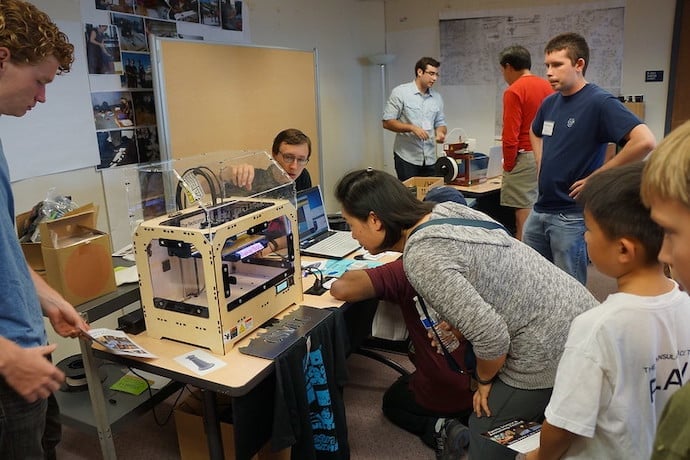

The way 3D printing works is that you start with a design, you turn the design into code for the 3D printer, and then the 3D printer creates the design—usually by laying down layers of plastic one after another to build the object from the bottom up.

This means that a 3D printer is very general. You can play around with designs quickly and do trial and error dozens of times within days not months. That’s exactly what Prusa did and they were able to quickly refine their design into one that the Czech government approved of, which by extension meant that other governments around the world felt comfortable using their design.

The downside, though, is that a 3D printer is actually very slow relative to the kinds of manufacturing—like injection molding—that you’d find in large scale manufacturing.

So the two are complementary: makers across the world started making face shields quickly to support the immediate need while other forms of production came along. That’s actually what happened, almost five weeks after I started making PPE! I was told on a Thursday afternoon that there was finally enough PPE and that the supply chain was recovering from the increased need, and thus I was politely fired from my volunteer position.

Even though this was a terrible time, I think there’s something very heartening about the way people came together to solve a problem we had never seen before with technology that was invented in our lifetimes.

Now, I wanted to focus on 3D printing in this article but do you know what other technology has been incredibly important to keeping people safe during the COVID-19 outbreak? Sewing machines! Yes, sewing is just as much a part of the maker movement as a 3D printer or laser cutter, and to do my part I even learned how to sew & repair sewing machines in order to help with the effort. We made cloth face masks that were given to people who needed them throughout the city, including at residential care facilities for the elderly.

During that five weeks I learned so much about 3D printing, maintaining & repairing printers, debugging slices that didn’t work right, and figuring out the right balance of speed & durability for the prints. 3D printing is a wild world still, one where we’re figuring out new tricks and ideas daily, and that means there’s a ton to learn and a lot to try.

Learn More

3D printed face shields

https://www.prusa3d.com/covid19/

3D printing for COVID masks

https://3dprint.nih.gov/collections/covid-19-response

3D printing for PPE

https://www.youtube.com/watch?v=CHDMdyN5Jjs

Facts about printing 3D medical devices

Makers create 3D masks: video

https://www.youtube.com/watch?v=p5rNrqENoco

3D Printed masks

First FDA-approved mask

https://governmentciomedia.com/fda-approves-first-3d-printed-mask-covid-19-support

3D masks and safety

https://www.ktlo.com/2020/04/27/safety-paramount-when-making-3d-printed-masks/

Why DIY 3D masks are risky

https://slate.com/technology/2020/04/diy-3d-printed-face-masks-shields-coronavirus.html